Microprilling VS Spray Drying: A Comparative Analysis of Processes and Products

Particle engineering plays a pivotal role in the development and manufacturing of a vast array of products across diverse industries. The ability to precisely control the physical and chemical properties of particulate materials is crucial for optimizing performance, stability, and processability of products. Among the various particle engineering techniques, spray congealing (often referred to as microprilling, spray cooling, or spray chilling) and spray drying stand out as prominent methods for transforming liquid feedstocks into solid particulate forms

These techniques are increasingly important in sectors such as pharmaceuticals, where they are utilized for controlled release formulations and bioavailability enhancement; food science, for encapsulation and powder production; and chemical industries, for the creation of specialty chemicals.

This article aims to provide a comprehensive comparative analysis of the fundamental principles, detailed processes, equipment requirements, resulting product characteristics, and inherent advantages and disadvantages associated with spray congealing (microprilling) and spray drying.

Microprilling

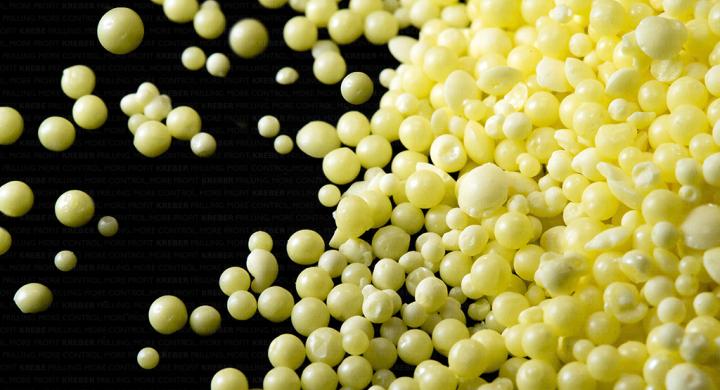

Microprilling, also known as spray congealing, spray cooling or spray chilling, is a solvent-free process that transforms a molten substance into well-defined solid particles by atomizing it into a cooling chamber where rapid solidification occurs. The process yields very small particles, typically with a median diameter (D50) of less than 0.5 millimeters. Unlike spray drying, which relies on the evaporation of a solvent to form solid particles, spray congealing depends on the phase transition of the atomized melt from a liquid to a solid state through rapid cooling. This fundamental difference in the mechanism of particle formation distinguishes spray congealing as a technique particularly suited for materials that are stable in a molten form and subsequently solidified.

Detailed Process Steps:

The spray congealing process generally involves four key stages: Feed preparation, atomization, cooling and solidification, and collection.

- Feed preparation: The feedstock for spray congealing is a feed of molten material, often called a melt. To prepare the material to be ready for spray congealing, melters or evaporators may be needed to get the material to the right temperature and purity. The molten state of the material is the highest temperature present in the process.

- Atomization: The melt is atomized into a cloud of fine droplets using an atomizer. Various types of atomizers can be employed, including pressure nozzles, two-fluid nozzles (also known as pneumatic or air nozzles), rotary atomizers, and ultrasonic nozzles. The selection of the atomizer type and the adjustment of its operating parameters, such as pressure and flow rate, are crucial for controlling the size and uniformity of the droplets, which directly influence the characteristics of the final solid particles.

- Cooling and Solidification: The atomized droplets are then introduced into a cooling chamber where they come into contact with a cold gas, such as air or nitrogen, or another suitable cooling medium. This rapid exposure to a lower temperature environment causes a sudden drop in the temperature of the droplets, leading to their rapid solidification into nearly spherical solid micro-particles. The rate of cooling is a significant factor that affects the particle morphology, crystallinity, and any potential residual moisture content. In some systems, a closed-loop configuration is used for the cooling medium, ensuring near-zero emissions.

- Collection: Finally, the solidified particles are separated from the cooling gas stream. This separation is commonly achieved using a cyclone separator and/or a bag filter. The collected particles, now in a solid particulate form, are then ready for further processing, such as tableting or encapsulation in prills, or for direct packaging.

Spray Drying

Spray drying is a widely used method for transforming a liquid feed, which can be a solution, suspension, or emulsion, into a dry powder by rapidly drying it with a hot gas. The fundamental principle behind spray drying is the evaporation of the solvent, typically water or an organic solvent, from the atomized liquid droplets when they come into contact with a hot drying gas, leaving behind solid particles of the solute or suspended material. This technique is particularly favored for drying thermally-sensitive materials, such as many foods and pharmaceuticals, due to the very short exposure times to high temperatures during the drying process1.

Detailed Process Steps:

The spray drying process typically involves very similar processing steps as compared to microprilling, with one distinct difference in the solidification step: feed preparation, atomization, drying, and separation and collection.

- Feed Preparation: The first step in spray drying is to prepare liquid feed. This involves ensuring that the material to be dried is in a suitable liquid form, either as a solution where the solid is dissolved in a solvent, a suspension where fine solid particles are dispersed in a liquid, or an emulsion where two or more immiscible liquids are dispersed. The concentration and viscosity of the feed are important factors that can influence the subsequent atomization and drying processes. In some cases, the feed may undergo pre-heating or homogenization to optimize its properties for spray drying.

- Atomization: Similarily to spray congealing, the liquid feed is then atomized into a fine spray of droplets. Various types of atomizers are employed to achieve this, including rotary disk atomizers, pressure nozzle atomizers, two-fluid nozzle atomizers, and ultrasonic nozzles. The choice of atomizer depends on factors such as the viscosity and flow rate of the feed, as well as the desired droplet size and particle size distribution in the final powder.

- Drying: The atomized droplets are then introduced into a drying chamber where they come into contact with a stream of hot drying gas. The drying gas is usually air, but for materials that are flammable or oxygen-sensitive, inert gases like nitrogen or argon may be used. The hot gas provides the necessary heat for the rapid evaporation of the solvent from the surface of the droplets. The contact between the droplets and the hot gas can occur in different flow configurations, including co-current flow (where the gas and liquid flow in the same direction), counter-current flow (where they flow in opposite directions), or mixed flow. The rapid evaporation of the solvent leads to the formation of solid particles.

Separation and Collection: After the drying process, the solid particles are separated from the moist exhaust gas. This separation is typically achieved using cyclone separators, which utilize centrifugal forces to separate the powder from the gas stream, and/or bag filters, which trap the fine powder particles. The collected dry powder is then ready for packaging or further processing as needed. In some cases, spray dryers may be combined with fluidized beds for secondary drying or to promote agglomeration of the powder particles.

Product Characteristics

The characteristics of the final products obtained from spray drying and spray congealing differ significantly due to the fundamental differences in their mechanisms of particle formation.

Particle Shape and Morphology:

While both technologies manufacture powdered products, both have very distinct shapes with morphologies, leading to its own benefit.

Spray congealing often results in the formation of nearly spherical solid particles. This spherical shape is primarily due to the solidification of molten droplets under the influence of surface tension. The surface of these particles can be either smooth or wrinkled, depending on the product and process.

Spray drying, on the other hand, is capable of producing a wider variety of particle shapes and internal structures. Depending on the drying conditions and the formulation of the feed material, spray-dried particles can be dense, hollow, or porous. Their shapes can range from spherical to wrinkled, shriveled, collapsed, or cenosphere (doughnut-like) and is generally harder to control as compared to spray congealing.

Density and Flowability:

Spray congealing often yields particles with excellent "free-flowing" properties and a low tendency to stick or agglomerate, due to their spherical form and relatively polished surface. These characteristics are highly advantageous for the storage, handling, and processing of the material. High bulk density can also be achieved with spray-congealed products.

Spray drying can result in powders with varying degrees of flowability, which depends on factors such as particle size, shape, and moisture content. Smaller particles produced by spray drying may exhibit poor flowability and can lead to a dusty product. To overcome these issues, agglomeration techniques are sometimes employed to improve the flow properties of spray-dried powders.

Moisture Content:

As spray congealing is a solvent-free process, the resulting products typically have very low or negligible residual moisture content. This is a significant advantage for the stability of many products. Spray drying aims to produce dry powders with a low moisture content to ensure their stability and prevent microbial growth. However, some residual moisture content in spray-dried powders can be influenced by the drying parameters and the nature of the feed material.

Stability and Purity:

Spray congealing, due to the absence of solvents and the often-lower processing temperatures compared to some spray drying applications, can be particularly beneficial for maintaining the stability of certain active ingredients. The low porosity of the formed powder yields the lowest possible tendency for oxidation on the surface of the material.

Advantages and Disadvantages

Both spray congealing (microprilling) and spray drying offer distinct advantages and face certain limitations, which are crucial considerations when selecting the appropriate technique for a specific application.

Microprilling

Advantages:

- Spray congealing is a solvent-free process, which eliminates the need for handling and recovering solvents, thus reducing potential toxicity and environmental concerns. It is often considered a relatively inexpensive, simple, one-step process with lower time and energy requirements compared to some other methods, including spray drying depending on process conditions.

- The technique is capable of producing spherical, free-flowing microparticles with good handling and storage properties.

- Spray congealing is easily scalable for continuous manufacturing and can often be implemented using modified spray drying equipment. The lower processing temperatures involved can be beneficial for certain materials.

Disadvantages:

- A primary limitation is that spray congealing requires the feed material to be molten, which may not be suitable for all substances or could lead to thermal degradation of heat-sensitive compounds if the required melting point is too high.

- In terms of morphology, the porosity is hard to control, as the products are the result of a solidification process2

Spray Drying

Advantages:

- Spray drying is a highly versatile technique suitable for a wide range of liquid feeds, including solutions, suspensions, and emulsions. It is a continuous process that can be easily scaled up for large-scale production.

- Spray drying offers the ability to control porosity of the powder by adjusting various process parameters.

- It reduces the volume and weight of liquid products, thereby extending their shelf life.

Disadvantages:

- A significant drawback of spray drying is the use of solvents, which can pose safety, environmental, and toxicity concerns. Solvent recovery or disposal can add to the overall cost and complexity of the process. The initial equipment investment and maintenance costs for spray drying systems can be relatively high as compared to spray cooling, depending on the application. Spray dryers can have lower thermal efficiency due to the large volumes of hot air used.

- While suitable for many heat-sensitive materials, the high processing temperatures can still degrade some compounds. Spray drying can sometimes result in powders with poor flowability and dust issues, and in certain cases, additional downstream processing steps may be required3.

Conclusion

In summary, while both spray congealing (microprilling) and spray drying are valuable techniques for producing solid particulate forms from liquid feedstocks, they differ fundamentally in their core principles. Spray drying relies on the evaporation of a solvent using hot gas, whereas spray congealing involves the solidification of a molten material through rapid cooling. Consequently, the typical feed materials and the resulting product characteristics vary between the two methods. Spray drying is generally used with solutions, suspensions, or emulsions, yielding powders with a broader range of particle sizes and morphologies. Spray congealing, on the other hand, requires a pure molten feed and typically produces more spherical, free-flowing particles, often in the micrometer size range.

When selecting the appropriate technique, several critical factors must be considered. These include the properties of the material to be processed, such as its melting point, heat sensitivity, and solubility; the desired characteristics of the final product, including particle size, shape, flowability, and stability; and various process considerations like cost, scalability, and environmental impact.

Ultimately, a thorough understanding of the principles, processes, advantages, and disadvantages associated with both spray congealing (microprilling) and spray drying is essential for making informed decisions in product development and manufacturing, allowing for the selection of the most appropriate technique to achieve the desired product attributes and process efficiencies. 2, 3

Take Your Particle Production Technology to the Next Level with Kreber Microprilling

Choosing the optimal particle production technology is critical for optimizing your product quality, product performance and your production process. While both spray drying and microprilling (spray congealing) offer distinct advantages, microprilling provides a solvent-free, thermally controlled approach that yields highly uniform, free-flowing microparticles with minimal residual moisture—ideal for applications in pharmaceuticals, food science, and specialty chemicals.

At Kreber, we offer a data-driven microprilling development process, ensuring a scientifically rigorous approach to help you make informed decisions and achieve superior results. Our process includes:

- Material Characterization – In-depth laboratory analysis to assess key physical parameters.

- Pilot-Scale Sample Production – Ensuring feasibility and performance before full-scale implementation.

- Customized Process Optimization – Tailored solutions to meet your specific product needs.

References

1 Bertoni S, Albertini B, Passerini N. Spray Congealing: An Emerging Technology to Prepare Solid Dispersions with Enhanced Oral Bioavailability of Poorly Water Soluble Drugs. Molecules. 2019 Sep 25;24(19):3471. doi: 10.3390/molecules24193471. PMID: 31557815; PMCID: PMC6804277.

2 Candiani A, Milanesi A, Foglio Bonda A, Diana G, Bari E, Segale L, Torre ML, Giovannelli L. Solid Lipid Microparticles by Spray Congealing of Water/Oil Emulsion: An Effective/Versatile Loading Strategy for a Highly Soluble Drug. Pharmaceutics. 2022 Dec 14;14(12):2805. doi: 10.3390/pharmaceutics14122805. PMID: 36559298; PMCID: PMC9785713.

3 Favaro-Trindade, Carmen & Junior, Fernando & Okuro, Paula & Dias-Ferreira, João & Cano, Amanda & Severino, Patrícia & Zielińska, Aleksandra & Souto, Eliana B.. (2021). Encapsulation of Active Pharmaceutical Ingredients in Lipid Micro/Nanoparticles for Oral Administration by Spray-Cooling. Pharmaceutics. 13. 1186. 10.3390/pharmaceutics13081186.

Explore the full potential of microprilling for you manufacturing needs.

With a top team of researchers and engineers, Kreber can determine the best solution related to the specifications of your request.

This is explicitly done with the Kreber Prilling Material Properties (PMP) document, resulting in a basic design of the prilling process. Based on this basic design, we can determine the capacity, the average prill size and the mechanical design for your new prilling equipment.

The Consultancy Study includes:

- Preliminary Piping and Instrumentation Diagram Drawings (P&ID)

- Preliminary General Arrangement Drawings (GAD)

- Additional Service: ROI, TCO calculation.

Please note that the Kreber Consultancy Study can be combined with the Kreber Lab-Scale Test, to gain even more insights about the feasibility and cost-effectiveness of the prilling process.

We look forward to providing you with advice and a solution tailored to your needs.

Grinding

In the realm of particle technologies, size reduction of solids plays a crucial role in transforming raw materials into refined products with improved properties.

This process involves reducing the size of solid materials to enhance their functionality, facilitate handling, and enable further processing. Among the various techniques used for size reduction, grinding stands as a cornerstone, offering unparalleled precision and versatility.

Understanding Size Reduction

Size reduction is the process of reducing the dimensions of solid materials, resulting in smaller particles or pieces. It encompasses a wide range of operations, including grinding, crushing, milling, cutting, shredding, and more. By breaking down solids into smaller sizes, size reduction facilitates better material handling, increases surface area for efficient reactions, improves uniformity, and enables the extraction of valuable components.

The Role of Grinding in Size Reduction

Grinding, one of the primary methods of size reduction, involves the application of mechanical forces to break down materials into smaller particles. This process utilizes grinding media, such as balls, rods, or abrasive grains, to physically impact, compress, or shear the solid material, resulting in size reduction. The Kreber grinder offers options to break up using mechanical force or knives to reduce the size of the products into a set size and shape.

Smaller particles are easier to handle and move around. Grinding makes materials more manageable for transportation and mixing.

Grinding increases the surface area of materials, allowing for faster and more efficient reactions, like chemical reactions or dissolution.

Grinding helps achieve a more uniform particle size distribution, ensuring consistency in the final product.

Grinding can help extract valuable components from solid materials, like minerals from ore or precious metals.

Grinding works with a wide range of materials and allows precise control over the final size, shape, and distribution of particles.

Grinding is a cost-effective method compared to other techniques. It requires less energy and equipment, making it economically viable. By using grinding to reduce the size of materials, we can create refined products with improved properties in various industries such as mining&minerals, food, pharma, chemical & recycling processes.

One of the ways to define yield is by the fraction of the solute in the feed that is ending up in the final product. The fraction of solute in the feed that remains in the solution can then be considered as the loss.

The crystal structure, size, shape and purity can be used to express the particle product quality of a crystalline product. Customer and manufacturer specification for a crystalline product can usually be related to these four product quality aspects.

The crystal structure for instance impacts properties such as solubility, shelf life and bioavailability of a pharmaceutical compound. A crystal size distribution gives information on the collection of crystal sizes in the product, which is for instance an important parameter in determining the dissolution behavior of fertilizers and pharmaceuticals.

The crystal shape can be vital for flow and storage properties of a product. In the food, pharmaceutical and fine chemical industries high levels of purity are desired. For instance, impurities from side reactions during the synthesis of an active pharmaceutical ingredient could lead to unwanted additional biological activity of the administered drug if they end up in the final product.

Analytical techniques can be employed to measure and control particle product aspects throughout the manufacturing process.

Process parameters have a strong impact on the particle product quality. By understanding the relationship between process parameters and particle characteristics, manufacturers can optimize their processes to consistently produce high-quality particle products.

A higher supersaturation during a crystallization process might for instance lead to a larger nucleation rate and therefore more particles and a product with a smaller average size. However, a higher supersaturation speeds up crystallization, increasing productivity.